A new and patented method for the production of the important mRNA vaccine component pseudouridine is more efficient, sustainable and cost-effective than the previously used chemical synthesis.

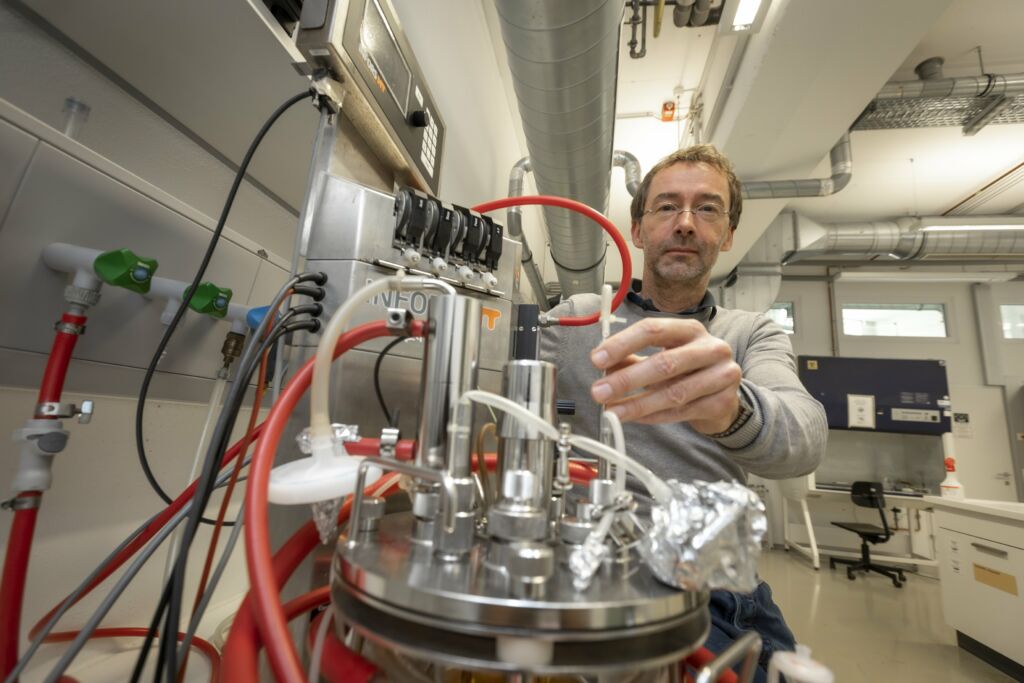

Researchers from the Institute of Biotechnology and Biochemical Engineering at TU Graz and the Austrian Centre of Industrial Biotechnology (acib) have developed a novel method for the production of central components of mRNA vaccines. They have also applied for a patent.

In an article published in the specialist journal Nature Communications, Nidetzky, Martin Pfeiffer and Andrej Ribar explain how they produced the essential mRNA vaccine ingredient pseudouridine by means of biocatalytic synthesis and created an alternative to the previous method of chemical synthesis.

One-step process

The alternative offers some distinct advantages. The chemical synthesis of pseudouridine not only involves toxic reagents and rare raw materials, but is also very energy- and time-consuming due to the necessary four to eight process steps and cooling to minus 20 degrees.

Biocatalysis, on the other hand, requires only one process step with four parallel reactions that take place at room temperature. In addition, only four enzymes are needed as catalysts (uridine phosphorylase, phosphopentose mutase, pseudouridine monophosphate glycosidase and phosphatase). These can be produced quite easily with E. coli bacteria. Biocatalysis also produces no waste materials; the only waste is phosphate, but this is recycled during the catalysis process.

Another important advantage is efficiency. Since the chemical production of pseudouridine converts the naturally-occurring uridine, which is less efficient for vaccines, there is no 100% yield during the conversion process. However, due to the smaller number of process steps, biocatalytic synthesis achieves a yield of 92 to 95%, compared to just 40 to 50% for the chemical processes published so far.

Inspiration from nature

The researchers based the new process on one of their earlier studies in which they discovered that the YeiN enzyme is a biocatalyst for the production of C-nucleotides. Since pseudouridine is the C-nucleoside of the RNA building block uridine, they had the idea of taking uridine, which can be produced in large quantities by bacterial fermentations, as a raw material and re-establishing the bond between its basic building blocks. The inspiration came from nature.

Unlike pseudouridine, uridine has an N-glycosidic bond, which is cleaved into ribose-1-phosphate (sugar) and uracil during natural degradation in cells by means of the enzyme uridine phosphorylase. Then the enzyme phosphopentose mutase rearranges the ribose-1-phosphate to ribose-5-phosphate, which is metabolized in the cells. This is followed by the application of the YeiN enzyme, which is used to link the ribose-5-phosphate and the uracil to pseudouridine-5-phosphate. Finally, phosphatase is used to split off the phosphate from the pseudouridine. Since pseudouridine is much less water-soluble than uridine, it simply crystallizes in the course of the reaction and can therefore be easily obtained by filtering the reaction supernatant.

Large scale production of pseudouridine could make mRNA vaccines cheaper

“Our work shows that biocatalysis is a potent alternative to the chemical synthesis of C-nucleotides such as pseudouridine,” said Bernd Nidetzky, head of the Institute of Biotechnology and Biochemical Engineering at TU Graz.

“We hope to implement the production on a larger scale soon and thus make pseudouridine available sustainably and cheaply in larger quantities. This could possibly also make the production of mRNA vaccines cheaper in the medium term, as potential partners from industry could implement our application quite promptly.”

Looking to expand your network?